One of my first posts in this blog was regarding the servicing of the Pioneer PL12D turntable, and that has proven to be the most popular by a significant margin. The Pioneer PL12D had its competitors, and probably the most popular alternative was the Trio Kenwood KD-1033 turntable. I use both names (Trio and Kenwood) as the company operated under different names in different markets. In the UK they were Trio, possibly because the brand Kenwood was most famous here for food blenders. 95% of a KD-1033 is similar to Pioneer PL12D, and servicing them is very much the same process. Both are belt drive , have an AC synchronous motor, mechanical speed change , a main bearing, sprung top deck and rubber motor mounts. the KD-1033 uses a different type of anti skate mechanism, employing a thread and weight. The plinth is shallower with an internal cross brace. One aspect that is different is the design of the main bearing, and servicing it is a little harder than a PL12D. The ...

The Sonab 85S turntable

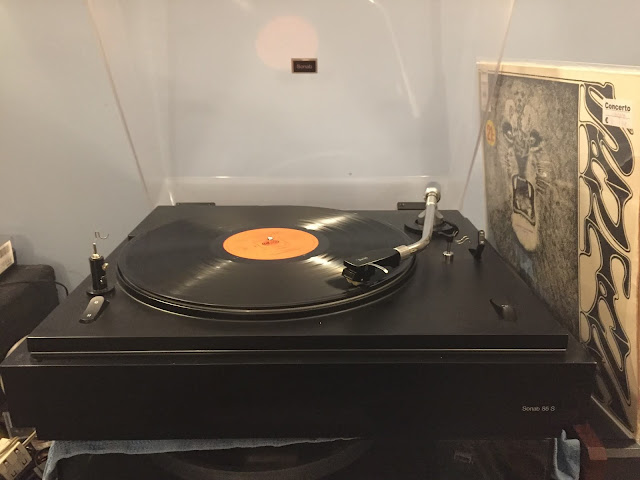

You'll see from this blog that I'm interested in vintage audio equipment , especially turntables and speakers. I keep an eye on ebay for potential bargains, and saw this turntable listed quite close to me and for a very good price, £60 buy it now, including 45 adapter, dust bug, DIN adapter, record clamp and a very nice Shure M95 cartridge. Condition listed as very good and with the original sonab headshell.

I've been interested in this deck for sometime, as to my eyes , it's a particularly nice design, with the very simple tonearm and deep chassis. I was aware that the model , from the late 70's was a cooperation between Swedish manufacturer Sonab and Yamaha. I don't know how much was contributed by which firm, but the same deck, or one very similar is also to be found as the Yamaha CP-500, though typically in teak rather than black. There were two Sonab models , the 75 and 85, the former being a manual deck, the latter an automatic, and these roughly align with the CP-500 and 700 models from Yamaha, though the latter has a different tonearm.

I bid for the auction, won, and collected it from the seller Harry who was a delight, looking after it for me during covid19 lockdown, and observing correct distancing. The deck was in superb condition, but Harry admitted he'd had some problems setting the tracking weight (more of this later). I am delighted with it.

I wanted to give the deck check over. My plan is that this will be a deck for my son when he moves out. I already have some speakers (KEF Cresta covered in a previous blog Kef Cresta restoration ).

I put it on my bench and powered it up, not connected to an amplifier, and everything worked fine. Its automatic, so you can simply put a record on move the arm to the play position and press the front right hand rocker switch. This both starts the platter and lowers the tonearm. At the end of a side the arm is raised, returned to the rest and the platter stopped.

I've been interested in this deck for sometime, as to my eyes , it's a particularly nice design, with the very simple tonearm and deep chassis. I was aware that the model , from the late 70's was a cooperation between Swedish manufacturer Sonab and Yamaha. I don't know how much was contributed by which firm, but the same deck, or one very similar is also to be found as the Yamaha CP-500, though typically in teak rather than black. There were two Sonab models , the 75 and 85, the former being a manual deck, the latter an automatic, and these roughly align with the CP-500 and 700 models from Yamaha, though the latter has a different tonearm.

I bid for the auction, won, and collected it from the seller Harry who was a delight, looking after it for me during covid19 lockdown, and observing correct distancing. The deck was in superb condition, but Harry admitted he'd had some problems setting the tracking weight (more of this later). I am delighted with it.

What is inside ?

I wanted to give the deck check over. My plan is that this will be a deck for my son when he moves out. I already have some speakers (KEF Cresta covered in a previous blog Kef Cresta restoration ).

I put it on my bench and powered it up, not connected to an amplifier, and everything worked fine. Its automatic, so you can simply put a record on move the arm to the play position and press the front right hand rocker switch. This both starts the platter and lowers the tonearm. At the end of a side the arm is raised, returned to the rest and the platter stopped.

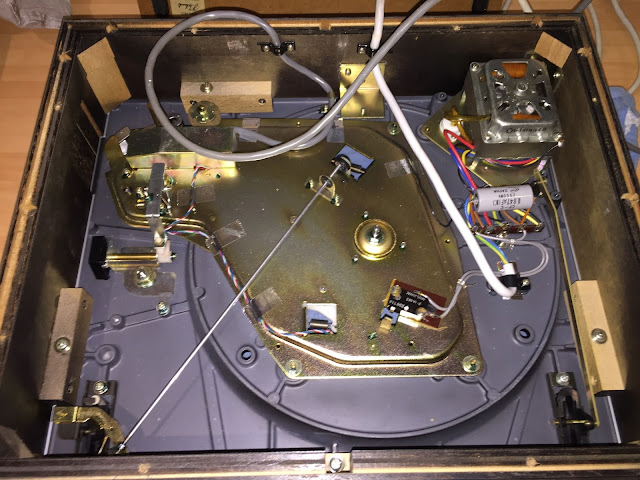

In the picture above, having removed the mat, platter and belt you can see the mechanism.

The deck is belt driven from an AC synchronous motor (top left) which is suspended by 3 springs. There is a speed change arm which moves the belt between two pulley positions , as per the Pioneer PL12D and JVC JL-A1. The main bearing and arm are attached to a suspended sub-chassis decoupled by 4 springs. You can see 3 of them with foam "doughnuts" at the top of each, I assume providing some damping. The 4th is hidden closer to the tonearm. The White nylon cogs drive the automatic return mechanism as per the JVC. This deck didn't have the original shipping bolts, but I shipped the deck myself in my car. My friend David Harris , who also restored one around this time, had issues with the shipping bolts deforming the cueing lever.

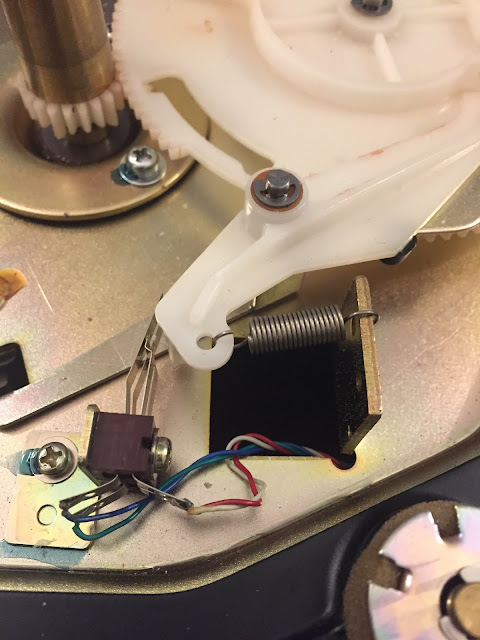

This example didn't seem to need any additional oiling to the mechanism, which worked fine. The main bearing has an oil reservoir felt washer beneath the small white cog, and I applied some sewing machine oil to this. It's not easy to remove the main bearing , as it is with the PL12D, as you would need to remove some of the automatic mechanism too. Possibly this is easier to do on the Sonab 75S, the manual version, but I left it be this time. Another feature of the 85S is auto-mute, where the signal from the cartridge is cut when the arm is not in contact with the record. This avoids you having to manually mute the turntable by always turning the volume to zero when not in use, something I instinctively do. The idea is not to have a "thump" noise go through the speakers when the stylus first contacts the record surface. You can see the wires and contacts in the picture at the bottom between the two lower springs. a set of microswitches make/break the signal wires at this point, driven by a white nylon lever tracking the arm movement.

I should mention at this point an excellent blog on servicing this deck at liquidaudio.com.au

This example didn't seem to need any additional oiling to the mechanism, which worked fine. The main bearing has an oil reservoir felt washer beneath the small white cog, and I applied some sewing machine oil to this. It's not easy to remove the main bearing , as it is with the PL12D, as you would need to remove some of the automatic mechanism too. Possibly this is easier to do on the Sonab 75S, the manual version, but I left it be this time. Another feature of the 85S is auto-mute, where the signal from the cartridge is cut when the arm is not in contact with the record. This avoids you having to manually mute the turntable by always turning the volume to zero when not in use, something I instinctively do. The idea is not to have a "thump" noise go through the speakers when the stylus first contacts the record surface. You can see the wires and contacts in the picture at the bottom between the two lower springs. a set of microswitches make/break the signal wires at this point, driven by a white nylon lever tracking the arm movement.

I should mention at this point an excellent blog on servicing this deck at liquidaudio.com.au

Having previously removed the platter, belt and mat, I removed the headshell, clamped the arm in place, and put a soft towel down on the work surface so I could flip the deck upside down supported by the dust cover. I removed the base board by taking out 8 screws, exposing the internal workings. I couldn't find a picture of the inside online, so here you go, a possible internet first !

It's similar to both the Pioneer PL12D and JVC JL-A1 in a number of regards. All are belt drives using an AC synchronous motor. This spins at a fixed speed determined by the mains frequency (50Hz Europe, 60 Hz USA and Japan has both 50 and 60 Hz regions). Top right you can see the motor which is suspended on springs rather than rubber mounts, so no need to restore hardened rubber . Interestingly the top and bottom motor bearings are fed oil via two pipes with a wick down the centre, which lead to the oil point accessible from the top of the deck.

It's similar to both the Pioneer PL12D and JVC JL-A1 in a number of regards. All are belt drives using an AC synchronous motor. This spins at a fixed speed determined by the mains frequency (50Hz Europe, 60 Hz USA and Japan has both 50 and 60 Hz regions). Top right you can see the motor which is suspended on springs rather than rubber mounts, so no need to restore hardened rubber . Interestingly the top and bottom motor bearings are fed oil via two pipes with a wick down the centre, which lead to the oil point accessible from the top of the deck.

The deck is well made, the top plate is a cast alloy rathen then pressed steel. The layout is tidy, with what appears a single capacitor the only other electronic component. This capacitor is in fact two in a single unit, providing both the phase to the motor (spins in the correct direction) and suppression of EMI from the switch. The based of the tonearm is encapsulated in a metal screen. My only criticism is the auto-mute, which necessitates the arm wiring making a huge detour out of the screened can to where the microswitch is close to the front of the deck. This "feature" proved problematic later as I had feared, I'm not a fan of auto anything as it tends to be the first thing to fail.

Having inspected the inside , I put everything back and did some basic tests.

Speed

I use a strobe disc to measure speed. There are mobile apps, which can do a good job, but I think work best with rigid decks like Technics SL1200, Rega, Project . Decks which have suspension where the replay system (platter, bearing,sub-chassis and tonearm) can float, seem to give variable results. I think this is because the off-centre weight of the phone on the platter creates an oscillation of the platter relative to the motor. The drive belt ois being flexed once per revolution, which gives erratic results

My strobe test showed that the deck was slightly fast on both 33 and 45 settings. This motor is synchronous, which means it always spins at a speed determined by the mains frequency , which for the UK is 50Hz. Hence any slight increase in speed is due to something in the geometry of the pulley, the belt and the platter belt rim. In the case of the Sonab the belt runs around the outside edge of the full platter. The first thing to check was that the motor pulley was clean and no fragments of previous belts were left on the surface, as these can fractionally increase the effective pulley diameter.

I used a wooden toothpick and a cotton bud soaked in some Isopropyl alcohol to thoroughly clean the pulley. There was a little bit of residue but not much, and after cleaning both the pulley and the platter rim, the deck still ran fast. Harry had provided an additional belt, but swapping these belts made no difference. Both looked perfect and were the same size. In this picture you can see the oil point for the motor , to the top right. The oil drops into a chamber which feeds the two pipes to upper and lower bearings

Past experience has taught me that not all replacements belts are created equal, so I went onto the online shop of William Thakker in Germany and ordered a new belt from them . I always use Thakker, in the past I have found their belts gave the correct speed, as with the PL12D, and their prices are cheap and reliable shipping to the UK. So I paused my testing of speed and started looking at the tracking

That tonearm

One aspect of the Sonab that is intriguing is the very simple, yet elegant tonearm. It uses a standard headshell, but in terms of adjustment there appears to be very little, just a slender balance weight at the back. The deck does infact incorporate anti-skate, which is adjusted via a screw under the platter. The arm felt reasonably good, there was a little play in the bearings but nothing serious. Now for the tracking weight.

Most tonearms have a balance weight with an adjustable dial on the front. You balance the arm, which establishes the null point where the arm floats. You set the dial to zero then rotate the weight AND the dial together to the required tracking weight i.e. 2 grams. With this arm there is no dial as such, simply markings on the weight, so I couldn't understand how you could set the tracking weight in the normal way. I decided the best way would be to use a simple stylus scales which I have, and then I hit the issue that Harry had mentioned. The arm will only lower when the platter is spinning, but in order to use a set of scales I need the platter to be still. The automatic mechanism seemed to be fighting me and my need to manually operate the deck. But with no power applied to the deck the arm just wouldn't lower from the cueing lever ? I should have read the manual, which explains the way around this, but I did discover it on my own. Basically you play a record with the power on, and when the stylus drops, you turn off power at the wall. Now the arm is "down " and you can use your scales. It's described in the manual which can be downloaded from vinyl engine

I set the tracking weight at 2 grams. The cartridge is a Shume M95 but the stylus is a replacement, possibly from Jico/Thakker Japan and these track a little heavier.

Another interesting point is the cartridge is not adjustable in the headshell. There are two sets of holes to allow to cartridge positions but not really any means to fine tune the alignment. Possibly it was fixed to make it easier, maybe the turntable shipped with one standard cartridge ? You can always it a slotted headshell as it uses the Universal connector, as originally developed by Ortofon and widely promoted by SME.

I decided to wait for the new belt before actually testing the deck via my amplifier

I set the tracking weight at 2 grams. The cartridge is a Shume M95 but the stylus is a replacement, possibly from Jico/Thakker Japan and these track a little heavier.

Another interesting point is the cartridge is not adjustable in the headshell. There are two sets of holes to allow to cartridge positions but not really any means to fine tune the alignment. Possibly it was fixed to make it easier, maybe the turntable shipped with one standard cartridge ? You can always it a slotted headshell as it uses the Universal connector, as originally developed by Ortofon and widely promoted by SME.

I decided to wait for the new belt before actually testing the deck via my amplifier

The new belt arrives

I fitted the new belt and tested the speed. It was much better, though still slightly fast. Comparing the 3 belts (2 that came with the deck + 1 from Thakker). This time the Thakker belt seemed to be longer in circumference, but the thickness seemed the same across all 3. With the PL12D I'd attributed the Thakker belts accurate speed being due to the belt being thinner and this small change having an effect on the relative diameter of pulley and platter . here the thickness appeared to be the same, though I would need a micrometer to confirm. perhaps the issue is the longer belt doesn't pull on the motor pulley as much and rides better on the centre ("crown") of the pulley ?

Anyway , once again, very pleased and good service from William Thakker

Playing some music

Anyway , once again, very pleased and good service from William Thakker

I fitted the deck into my system , I use an A&R Cambridge C200/SA200 pre-power amplifier, which conveniently comes with both RCA and DIN sockets for the phono input. This deck had a DIN plug on the end, which was probably original, but had been fitted with a female DIN to RCA adapter, which I discarded. It's possible the deck will be used with an amplifier with DIN inputs , an A&R Cambridge A60, so I see no reason to replace the original

One last thing

I used the deck for a few days, happily but started to notice some distortion coming from the right channel. Sometimes during music, sometimes when nothing was playing . It sounded like rustling leaves. I decided that this might be the auto-mute, which do sometimes tarnish or get dirty, or the contacts stick.

I removed the platter and used some card soaked in Isopropyl alcohol to rub between the contacts

I removed the platter and used some card soaked in Isopropyl alcohol to rub between the contacts

This seemed to improve things, but then I completely lost the right channel. This time I decided to be a little more methodical and took the headshell off. I used a digital multimeter to measure the resistance between the pins of the headshell connector. between right channel signal and right channel ground, left channel signal to left channel ground. one side had a resistance value, the other side was open circuit (infinite resistance). I disconnected and reconnected all the pins in the headshell and measured again , and now had a similar reading on both channels. I refitted the headshell, and since that the deck has played fine without loss of chanel or rustling sound. Perhaps I was too quick to blame the auto-mute ?

Conclusion

This deck is excellent. It's very well made, presumably by Yamaha, and the plinth is one of the most solid I have seen, much thicker than most, using plywood as opposed to chipboard. Also the top plate is very substantial. It looks fantastic and I think this is where Sonab had a lot of input, their speakers and amplifiers have a similar look which just looks right to me. The whole thing says quality, and that's confirmed by the fact it still works well after 40+ years. I could forgo the automatic features, as I've grown up with manual decks from my father's first Thorens TD150 in 1972. My reasoning is that while these features are nice, I'd rather have something simpler, with less things to go wrong, and for that reason I would suggest looking out for the Sonab 75s in preference, it looks the same but forgoes the auto features, meaning it's easier to service .

Comments

Does this sound likely to you? The capacitor seems to be rated at 2500V, can that be correct?!

i think it's likely the microswitch, and your options are either replace or possibly try getting some switch cleaner into it and exercise it a few hundred times with a probe like a wooden cocktail stick or pencil. Servisol 10 switch cleaner comes in an aerosol can and has a drinking straw tube which you can attach to the nozzle and direct right inside the switch. Sometimes they get gummed up with old grease. So I'd try that first.

The capacitor is a suppression cap , its job is to prevent arcing in the switch from causing a pop noise through your speakers. If you are not experiencing that, I'd leave it. The high voltage rating for this application is common and an equivalent modern suppression cap can be purchased for very little, look for a Y2 class suppression cap BUT I dont think a failure of the cap would cause your problem, so maybe best leave it

Good luck, and please keep us posted

Thanks for your reply. You were correct, it was the switch. There was no luck trying to clean it. In order to catch up with a backlog of records I hadn't listened to yet; I just removed the switch from the circuit, so it spins constantly when switched on at the wall.

My friend who is keen on electronics projects took the switch away. He has managed to drill the rivets out, and repair the faulty mechanism inside. I just need to get around to re-installing the switch.

Cheers!

Marcus,

I also have a Sonab 85S that is playing to fast and have never opened one before. I want to check the belt and see if I need to order one but cant seem to find anywhere information on how to place the belt back on as when I opened it it was already loose. Is it just along the speed mechanism then the turning part of the motor? Or is it also supposed to be around the 3 spocks(not sure if they're called that)? I live on a remote island where there is nobody who knows how to fix this. Any help would be highly appreciated.

Its a good idea to clean all the surfaces that the belt is in contact with, such as the motor pulley and the rim of the platter, using alcohol . if a previous belt has perished, as they sometimes do, any small lumps of the old belt left on the platter or pulley will affect the speed.

The old belt could probably use a clean, and a wipe through a cloth with some detergent , then a rinse will help remove any old oils or grease and restore a little grip to it. Platancelen print roller restorer is also an excellent product for this

To check the speed I prefer to use a strobe disk and either an old fashioned filament lamp as the light source or download a strobe app on my phone, set to the frequency I need (50Hz Europe /60Hz USA). There are speed check apps for phones , but on suspended decks, having the additional off-centre weight of the phone will affect the result.

I found the Thakker belts to be good, and generally seem to get decks back to the correct speed.

Good luck, and keep us posted with your progress

just stumbled across this excellent piece on the Sonab 85s, excellent stuff indeed!

my father bought one of these, along with a Sonab R4000 amp and OA5 speakers, in 1972(ish). They now sit proudly in my living room and, after a little fettling, sound great.

The only issue i have with it is that it won't auto return. The mechanism works fine, if you push the arm slightly beyond where it reaches when playing a record it clicks and returns as it should.

Would you know if this is something that can be adjusted and, if so, how?

Thanks again for a great blog! stephen

I need to buy a new belt basically, as it is very very loose around the platter and pulley, basically it just drops down. That's why I thought I had to maybe go around the spokes. So I will have to find one. Hope I can as I am in the Philippines and there's not many here. I will update you on how it goes :)

OK, well first of all it might be possible to rejuvenate the old belt a bit. Rubber seems to change with age, and this may differ from region to region based on climate. I'd imagine that the Philippines are warm and humid for much of the year, where Northern Europe tends toward cold and dry. It's good to clean the belt , I sometimes pour some isopropyl alcohol onto a clean rag and pull the belt through the wet part the rag so it removes any surface dirt from the belt. It is also important to clean where the belt contacts the platter and the pulley, these also must be very clean. Next try sealing the belt in a plastic bag with some liquid hand soap and massaging it so it is covered in the liquid soap, and leave for 30 minutes. Then rinse and immerse the belt in a cup of hot water. I know this all sounds like it's an elaborate joke, but this is how I restore the suppleness to the motor rubber mounts in a Pioneer PL12D and it might help to reinvigorate the old belt ?

lpgear.com are a large US-based supplier of belts and possibly they are easier for you in the Philippines.

A final and last chance option is to cut the belt and join with a slight overlap to remove a little slack. I have seen this done, and sometimes i work and is inaudible. Rubber glue as used in repairing bicycle tyres should work